Introduction

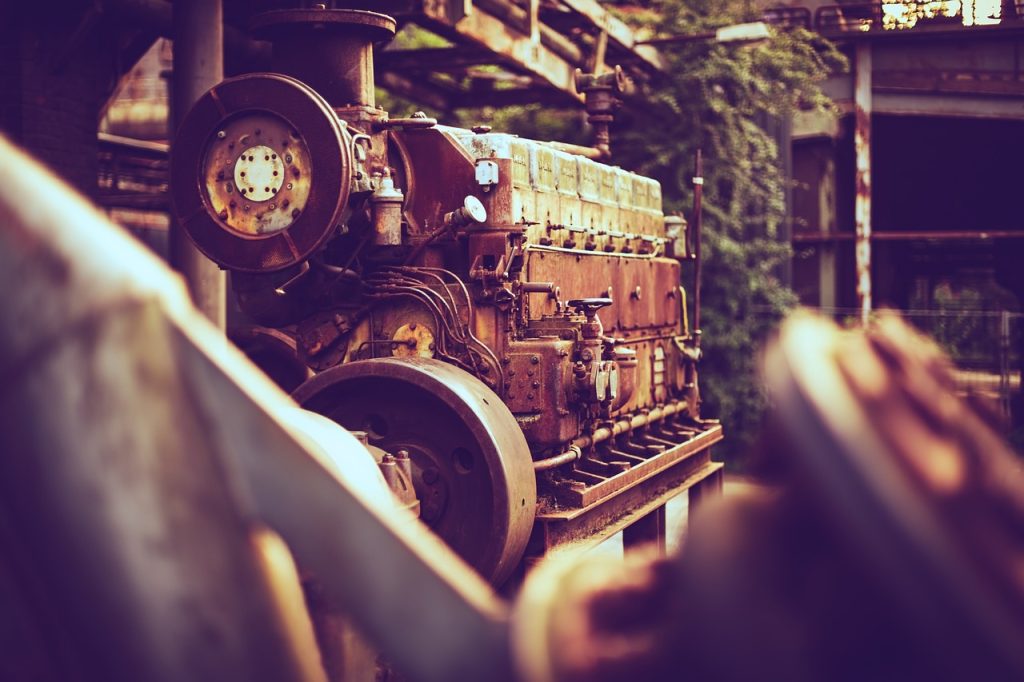

Diesel generators are essential power sources in various industries and applications, providing reliable electricity when grid power is unavailable or unreliable. However, operating diesel generators at high altitudes presents unique challenges due to decreased air density, lower oxygen levels, and temperature fluctuations. In this article, we will explore the factors that affect the performance of diesel generators at high altitudes and discuss strategies to optimize their operation for efficiency and reliability.

Understanding 500KW Diesel Generator For Sale -Altitude Operations

High-altitude locations are defined as areas situated at elevations exceeding 5,000 feet above sea level. At higher altitudes, the air density decreases, resulting in lower oxygen levels and reduced engine performance. Diesel engines rely on the combustion of air and fuel to generate power, making them particularly sensitive to changes in air density.

The reduced air density at high altitudes affects the engine's ability to draw in the necessary amount of oxygen for combustion, leading to incomplete fuel combustion, decreased power output, and increased fuel consumption. Additionally, lower oxygen levels can impact the engine's cooling system, potentially leading to overheating and reduced efficiency.

Challenges of High-Altitude Operation

Operating diesel generators at high altitudes poses several challenges that can affect performance, reliability, and longevity. Some of the key challenges include:

1. Reduced Power Output: The decreased air density at high altitudes results in lower oxygen levels, which can impair the engine's combustion process and reduce power output. This reduction in power output can limit the generator's capacity to meet the electrical demands of the load.

2. Increased Fuel Consumption: Incomplete combustion due to lower oxygen levels can lead to increased fuel consumption as the engine compensates for the reduced power output by burning more fuel. This can result in higher operating costs and reduced efficiency.

3. Overheating: High-altitude locations often experience temperature fluctuations, which can affect the engine's cooling system. Reduced air density can impair the cooling efficiency, leading to overheating and potential damage to engine components.

4. Starting Difficulties: Diesel engines require a sufficient amount of oxygen for combustion during the starting process. At high altitudes, the lower oxygen levels can make it challenging to start the engine, especially in cold weather conditions.

Optimization Strategies

To overcome the challenges associated with high-altitude operations, it is essential to implement optimization strategies that enhance the performance, efficiency, and reliability of diesel generators. The following strategies can help improve the operation of diesel generators at high altitudes:

1. Engine Calibration: Calibrating the engine parameters, such as fuel injection timing and air-fuel ratio, for high-altitude operation can optimize the combustion process and improve power output. Engine manufacturers may provide altitude adjustment kits or guidelines for adjusting the engine settings based on the altitude of the installation site.

2. Turbocharging: Installing a turbocharger on the diesel engine can help compensate for the reduced air density at high altitudes by compressing the air before it enters the combustion chamber. This increases the oxygen content, improving combustion efficiency and power output.

3. Cooling System Upgrades: Upgrading the engine's cooling system with larger radiators, improved fans, and enhanced coolant circulation can help prevent overheating at high altitudes. Ensuring proper cooling is essential to maintain the engine's performance and longevity.

4. Air Intake System: Optimizing the air intake system by installing high-performance air filters and ensuring proper airflow can improve the engine's combustion efficiency and reduce the risk of contaminants entering the system. Clean air intake is crucial for maintaining engine performance in high-altitude environments.

5. Fuel Quality: Using high-quality fuel with the appropriate cetane rating and low sulfur content is essential for optimal engine performance at high altitudes. Poor-quality fuel can lead to incomplete combustion, increased emissions, and reduced engine efficiency.

6. Regular Maintenance: Performing regular maintenance checks, including monitoring fluid levels, inspecting filters, and servicing components, is crucial for ensuring the reliable operation of diesel generators at high altitudes. Regular maintenance helps detect and address potential issues before they escalate and impact performance.

7. Cold Weather Preparations: High-altitude locations are often prone to cold weather conditions, which can affect the starting and operation of diesel generators. Preparing the generator for cold weather by using cold-weather fuel additives, installing block heaters, and ensuring proper insulation can help improve starting reliability and performance in low temperatures.

Case Studies and Success Stories

Several industries and applications rely on diesel generators for high-altitude operations, from remote mining sites to mountainous regions and off-grid installations. Implementing optimization strategies has proven successful in overcoming the challenges associated with high-altitude operation and ensuring the reliable performance of diesel generators.

One such success story comes from a mining company operating at an altitude of 10,000 feet in the Andes mountains. By upgrading their diesel generators with altitude adjustment kits, turbochargers, and enhanced cooling systems, the company improved power output, reduced fuel consumption, and enhanced reliability, ultimately increasing productivity and reducing operating costs.

In another case study, a telecommunications company operating cellular towers in high-altitude areas implemented regular maintenance schedules and cold weather preparations to optimize the performance of their diesel generators. These measures improved starting reliability, reduced downtime, and ensured uninterrupted power supply to the communication infrastructure.

Conclusion

Diesel generators are indispensable power sources for high-altitude operations, providing reliable electricity in challenging environments where grid power is limited or unavailable. Operating diesel generators at high altitudes presents unique challenges that can impact performance, efficiency, and reliability.

By understanding the factors that affect diesel generator operation at high altitudes and implementing optimization strategies such as engine calibration, turbocharging, cooling system upgrades, and regular maintenance, operators can enhance the performance and longevity of their generators in high-altitude environments.

As industries continue to expand into remote and high-altitude locations, the demand for optimized diesel generators for high-altitude operations will only increase. By staying informed about best practices and advancements in diesel generator technology, operators can ensure the efficient and reliable operation of their generators in high-altitude environments, contributing to increased productivity and reduced operational costs.